We choose bars and stones for sharpening knives

Content:

Every housewife knows how much easier and more enjoyable to cook, having a sharp knife at hand. However, even the highest quality blades eventually become dull and require immediate sharpening. To return the blade to its original state, use whetstones for sharpening knives. Today, the market for household goods has a huge selection of these tools. Sharpening stones vary in nature of origin, grain size and nature of the abrasive. Each of the devices has its own advantages and disadvantages, so the choice of bar must be approached very responsibly, based on the characteristics of the knife.

Grinding stones of natural origin

Sharpening stones are divided into natural and artificial by origin. Not always bars made of natural material are better than artificial sharpeners. This is easily explained, because the grains of a natural abrasive substance are heterogeneous and differ greatly in size.

To make a good tool, you need a stone whose length exceeds 20 cm, and such a holistic mineral has a rather high cost. In addition, natural stones are more fragile than artificial stones, so they often have to be edited and grinded by hand. Nevertheless, many prefer to have such devices and enjoy using a grinder made of natural stone.

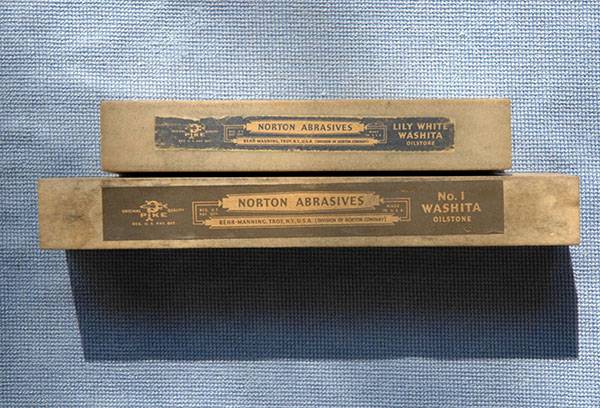

Arkansas (Novakulit)

The birthplace of Arkansas stone is the US state of Arkansas. The mineral consists of fine-grained quartz crystals having incredibly sharp edges and tightly connected to each other. Not everyone can use Novakulit. One must be a true master of his craft in order to sharpen a knife with such a tool with high quality.

When working in Arkansas, lubrication is required, the role of which is most often played by mineral oil. If this condition is not met, then the surface of the stone will quickly become contaminated with particles of the material being ground, and the tool will become unusable.

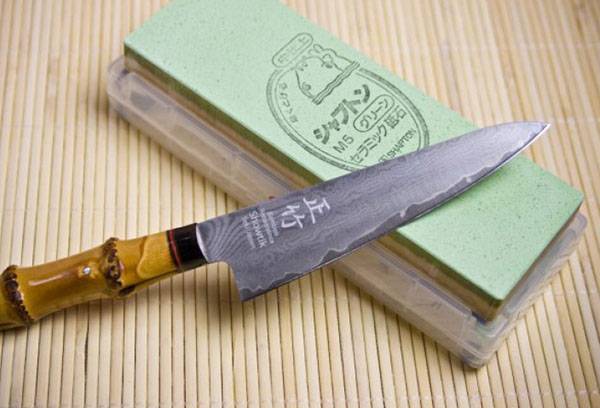

Japanese water stone

Another natural material used for sharpening knives is Japanese water stone. If this tool fell into the hands of an experienced grinder, then the speed and quality of sharpening will be ensured. For beginners, this version of the whetstone, like the previous one, is absolutely not suitable.

The fact is that Japanese water stones are very expensive and require special conditions of use. Do not forget to lubricate during operation. In addition, coarse-grained and medium-grained whetstones must be stored in water, which is recommended to be constantly changed, and fine-grained stones for sharpening knives, on the contrary, must be thoroughly dried after use.

Water stones are very soft and grind quickly, and grind unevenly. More abrasive material is grind off on one side, and less on the other. To bring the sharpening water tool to its original state, it is necessary to make a lot of efforts: find a marble plate with a flat surface, cover it with sandpaper, moisten it with water and straighten the whetstone, slowly moving it over the skin.

Artificial stones

Today, there are technologies for producing grindstone artificially. This significantly reduced the cost of the tool.Artificial stone - these are two abrasive materials mixed together, tightly connected under the influence of high temperatures and pressure.

As the working fraction using silicon carbide, corundum and chromium oxide. These materials are so strong that they can cut metal layers. To hold the working crystals in the bar, a special base is used.

Ceramic stones

Ceramic bars are durable and have a high quality metal surface finish, but lag behind other types of bars in several important ways.

- Sharpening with ceramic stones is a long and laborious process.

- Fine-grained ceramic stone is almost impossible to buy.

Of the advantages of ceramic grinding tools, one can note their low cost and unpretentiousness in use. This tool does not require lubrication or soaking and is often used instead of rubbish.

Today, a large number of ceramic whetstones made in China or Germany are on the market. Sometimes there are products manufactured back in the days of the Soviet Union. If you are lucky enough to get such a tool, you don’t have to worry about the quality of sharpening, since these products have excellent quality.

Ceramic bars are needed not only for straightening knives, but also for sharpening fishing hooks and needles. If under a stream of warm water rub two old stones against each other, then they can again be used.

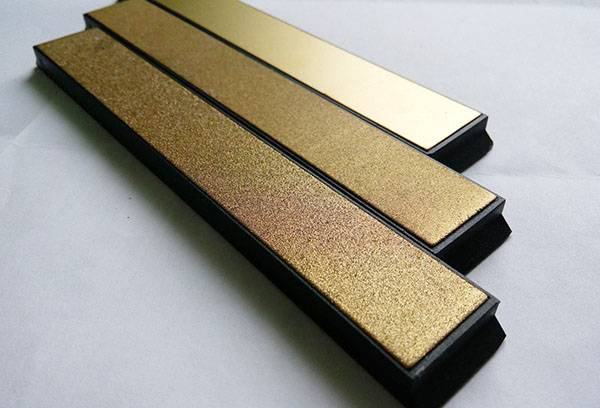

Diamond bars

Some ignorant people think that the diamond bar is studded with diamond crystals. However, this is far from the case. A diamond grinding tool is a plastic or aluminum substrate on which metal plates with a set of diamond abrasive grains are fixed on both sides.

A double-sided diamond bar is the best option for sharpening knives. Both an experienced master and a beginner can use it.

Diamond grinding stones have the following advantages:

- even after prolonged use, the diamond sharpener remains completely flat;

- diamond grains have very sharp edges and do not grind during operation;

- if a diamond bar is accidentally dropped, unlike a ceramic stone, it will not break into pieces;

- during sharpening, it is not necessary to moisten the sharpener with water or oil;

- to clean the diamond stone from particles of steel, it is enough to rinse it in clean water and wipe it dry with a piece of cloth;

- the diamond bar very quickly grinds the steel of the knife, so the surface of the bar remains in working condition for a long time.

Diamond sharpeners have a significant drawback. If a block falls into inept hands, the blade of a knife can be irreparably damaged. This is explained by the fact that diamond grains held on the surface of a stone with the help of electrolytically sprayed nickel are much stronger than steel and can scratch and even crush a knife blade.

Often diamond grinding stones are produced as part of a grinding machine, so you can meet and choose bars of various shapes and sizes on sale. In addition, complete with grinding tools can be sold and all kinds of mounts.

Diamond abrasive bars are durable, but they need time to grind. As soon as all poorly fixed grains fall out and the tool gets its normal shape, it will serve for many years and perform its work efficiently.

What is the granularity of a grindstone?

The granularity (or in another way "gritty") of the bars used for sharpening knives shows how many particles of abrasive substance are per 1 cm2 bar surface. This value ranges from 80 to 10,000 grit. The higher the grit, the smoother the whetstone and the smaller the size of the abrasive crystals.

Bars with a small grain size are used for initial processing of a cutting object, since they remove a thick layer of metal due to large particles. It is advisable to use them in cases where the blade is very dull or the cutting edge has crumbled.

Sharpening stones with a high grit value more carefully affect the metal. They are used for finishing the blade. If, when sharpening a knife, you have several bars with different grain sizes and use them in order of increasing grit, you can make the knife incredibly sharp.

Rules for sharpening a knife on a diamond bar

When sharpening a knife on a diamond bar, you need to follow a few simple rules - only in this case you can get a positive result.

- Before starting work, moisten the diamond bar with water, having previously dropped a little detergent for dishes or liquid soap into it.

- Having made more than ten movements, it is necessary to wash off the suspension formed on the bar under a stream of cool water.

- For the duration of the break, it is better to put the bar in a container with water.

- The grinding whetstone while editing the knife should not lie on the hand, but on a wooden board and have a solid support. It is inconvenient to hold a stone or a bar in your hand. This can be done in the case when it is impossible to find a solid and even surface for installing the bar, for example, in a campaign.

- During sharpening, you should use all the surfaces of the bar evenly, and not lean on only one edge, then the abrasive substance will grind evenly.

Important!

During sharpening, you should not press the knife with all your strength - this way you can break out the abrasive crystals from the bar and spoil the expensive tool.

- The new diamond bar requires a break-in. At first, he very aggressively removes the steel coating, but after sharpening 7-10 knives it will work more gently.

- The length of the sharpener should be equal to the length of the knife or slightly exceed it.

- For full and high-quality sharpening, three types of stones are used, which differ in the degree of granularity. They begin processing with coarse-grained stone, and end with a bar with the smallest crystals of abrasive.

- For daily editing of a knife blade it is necessary to have musat. This tool resembles a file and is used to bring the sharpness of the blade to its optimum state.

With grindstones with different grain sizes in your arsenal, you can always keep cutting tools in order. For experienced craftsmen who have to sharpen knives every day, expensive natural minerals like Arkansas or Japanese water stone are more suitable. It is advisable for a beginner to purchase a diamond block less whimsical to use.