How to make a mosquito net on a window or balcony with your own hands?

Content:

So that insects, poplar fluff, dust from the street do not fly into the apartment, the window should be equipped with a net. At the same time, it is not at all difficult to make mosquito nets on plastic windows with your own hands. If you know the assembly technology, it is quite possible to get by with the tools that are in every apartment. Frame materials are also affordable. Compare the advantages of the most common designs and choose the best option.

Should I bother with making the mesh?

Before you start making the grid for a window or balcony door yourself, it is worth evaluating the feasibility of such a solution. Today, the market for windows and window components is oversaturated: dozens of companies produce, assemble, install and repair windows from plastic or wood. Most of them also produce nets.

But there are several arguments in favor of the idea of making mosquito protection for a window on its own:

- One finished frame costs about 1.5 thousand rubles, so for a complete set for all windows and a balcony a fair amount is already obtained. Moreover, all components for work are inexpensive and are found in any hardware store. If you make the framework yourself, you can save a lot of money.

- In remote areas of the city and holiday villages, it is difficult to call a specialist to measure window structures. It is often faster to do the work yourself than to wait for a specialist.

- Knowing the design of the mesh made by hand, it is easier to carry out the necessary repairs.

If the house has small children, special attention should be paid to the safety of the structure. But even the highest quality grid is not a reliable barrier. Therefore, leaving the kids alone in a room where the window is closed only with a grid is strictly prohibited!

If you feel confident when working with tools, and also do not want to spend extra money and time, manufacturing grids will be a profitable option. Another plus is that you can independently think through all the nuances of the design.

Start with the project

No matter what work a person does, he will not succeed if he does not clearly understand what and how he needs to do. In the manufacture of protective mosquito frames, it is also necessary to accurately imagine all the stages of work and the parameters of the finished product. A pre-compiled project will help.

You can build a drawing of a future product on a piece of paper or in a specialized program. The following parameters must be displayed in the drawing:

- The geometric dimensions of the finished product and all parts of the structure.

- The exact number of all parts and fasteners.

- The material from which the frame and mesh fabric will be made.

- The method of attaching the structure to the window.

When designing, do not forget to leave allowances. Otherwise, it will not be possible to attach the canvas to the frame, and the finished mesh to the window.

A detailed project will help to correctly evaluate the budget spent on work, not to be mistaken with the amount of material, to do without annoying inaccuracies and omissions in the work. Therefore, this stage of work should be treated as responsibly as possible. Do not start production until the project is completely ready.

Choose a mesh cloth

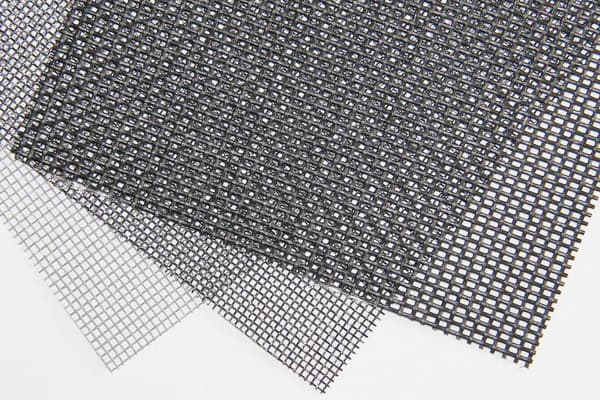

The effectiveness of the created protection against insects largely depends on the quality of the used mesh fabric.Today there are dozens of varieties on sale, differing in cell size, material and purpose. Not all of them are suitable for installation on windows.

Cell sizes range from 0.6 to 1.2 mm. The smaller the cell, the less risk that the insect will get inside. Cloths with a 0.25 mm cell can even trap dust without passing it into rooms. However, too small cells reduce the permeability of the canvas for light and air. In most cases, the best choice for installation on the windows of the living room will be material with cells of 0.6–1 mm.

The visual perception of the grid is also affected by color. Least of all the eyes notice a canvas of gray color. Therefore, in most cases, this particular shade is optimal for mosquito barriers.

Having decided on the color of the canvas and the size of the cells, pay attention to the material from which the canvas is made. Most often 4 options are used:

- Cotton. This natural material has a fleecy thread structure that gives extra protection against insects. In addition, cotton is not destroyed by ultraviolet radiation. However, this natural material dries slowly and becomes a suitable environment for the development of bacteria. Because of this, the service life of cotton nets is short.

- Polyester. This cheap polymer is widespread. He is chosen when you need "just a grid."

- Nylon. The fibers of this polymer are twisted and braided in a special way. Due to such weaving and hypoallergenic properties of the material itself, nylon nets will be an excellent choice for people suffering from allergies. They do not pass dust, pollen of plants and other allergens. The only drawback is the higher (compared to polyester) price.

- Fiberglass. The main difference between this composite material is high strength. Canvas with such properties (also called “anti-cat”) is chosen by pet owners who tend to climb the net or tear it with claws.

Thus, for most cases, a gray mesh fabric made of polyester with a mesh diameter of about 0.8 mm is suitable. It will create a fairly reliable barrier to insects and dust, while it will not be evident or trap light and air. To make a tent with a net over the bed, it is better to choose nylon, and in a house with active pets (cats, parrots, etc.), fiberglass nets should be preferred.

Determine the mesh design

Among the designs invented to date, there are two of the simplest to implement. Each of them has its pros and cons, but can be easily installed on a wooden or plastic window.

- The first option is soft frameless designs. The cellular canvas in them is edged around the edge with a special ribbon or cord. Such nets are easy to mount on the window. During storage, they take up little space. And the cost of this design is lower than the rest. However, there are significant disadvantages, the main of which is a short service life.

- Frame designs are more durable, since the canvas here is mounted on a special rigid frame. To fix such a design on the window frame can be movably (using hinges) or rigidly (using z-shaped brackets or corners). In production, insect frame screens are a bit more complicated, but most people with minimal experience with tools are quite capable of coping with this task.

The structures used in industrial manufacturing (rolled and pleated) are somewhat more complicated. Therefore, it is better for a person with minimal experience to dwell on the option involving the manufacture of a rigid frame with the subsequent tension of a cellular canvas. It is this option that we will consider in the future.

We select material for the frame

Today on sale you can find the profile from which the frames are made at enterprises manufacturing plastic windows. From such a profile (it is called MPF2), you can assemble a frame that will be indistinguishable from the factory one.But this option will not give significant cost savings, since the profile is relatively expensive. An alternative to it can serve as several improvised materials:

- Plastic cable ducts made of PVC. The cable channel frame is lightweight, easy to assemble, inexpensive, and has a decent appearance. We recommend this option to everyone who plans to make frames for mosquito nets on their own.

- Wooden whetstones. Wood is an environmentally friendly, durable and beautiful material. He is not afraid of water and microorganisms (with proper treatment) and is able to last for many years. There are two drawbacks in comparison with a plastic box: greater weight and processing complexity. But for wooden windows or doorways, this is quite an interesting option.

In the future, we will consider the process of manufacturing a frame frame from plastic boxes for cable laying. If you take wooden blocks as a material, the algorithm and the set of tools will have to be slightly changed.

The MPF2 profile has thicker walls than cable channels. Therefore, a makeshift frame will turn out to be somewhat less durable. In principle, this will not interfere with the normal use of the grid. But for fastening to the windows you will have to use not plunger latches, but z-shaped brackets.

Mosquito net tools

To make a frame for a mosquito screen with your own hands from a plastic channel, you will need a certain set of tools. Most of them are in every home. We will provide the most complete list that will allow you to perform all operations quickly, accurately and without unnecessary labor costs. But, in principle, some of these tools can be replaced.

So, for work you will need:

- rivet and rivet action (about 4 mm in diameter);

- a drill equipped with a rivet drill;

- miter box (this useful tool allows you to cut corners very accurately; if you don’t have one, you can buy a miter box at a construction materials store or make it yourself);

- hacksaw for metal;

- pencil, ruler, tape measure, square and construction level for marking operations.

In addition to tools, you need to prepare all the materials for work in advance:

- cable channel (suitable 15x20 mm) with a double lock;

- 4 connecting elbows;

- mesh cloth of the required size;

- steel or duralumin corners;

- Z-shaped brackets for attaching the finished screen to the window opening.

Work sequence

So, everything is prepared, and you can begin to work. The sequence of operations looks like this:

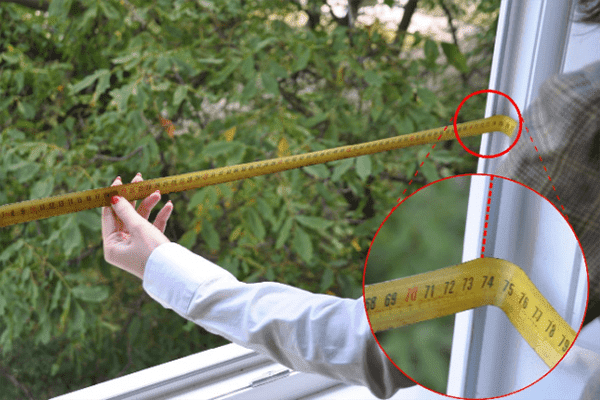

- Carefully measure the perimeter of the light opening. We make a 1/10 tolerance on each side. So we get the dimensions of our frame. For the canvas add another 3-5 cm on each side.

- We are building a drawing of the future design. Once again, we verify all sizes, make an estimate for the materials and fasteners.

- We buy everything necessary for work, we prepare the tool according to the list.

- Using a miter box with a hacksaw, we cut the boxes to specific sizes. At the ends, the saw cut is displayed at 45 ° to join the corners.

- We combine the boxes without covers in pairs, put reinforcing squares inside. We mark the holes, drill them with a drill. We check with a square that the boxes are aligned strictly at right angles.

- With a rivet we collect two opposite corners (in the form of the letter "G").

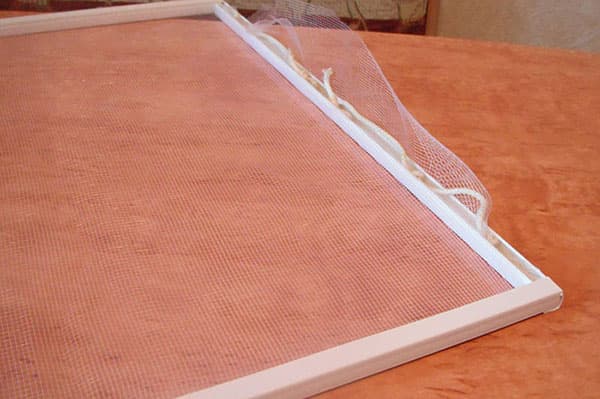

- Then, once again checking the corners, similarly collect the two remaining corners, getting the finished frame.

- The next stage is performed with assistants. Someone is holding a frame, someone is stretching a grid over it. The third puts on the cover box, carefully fixing the canvas on the frame.

- The insect screen is ready. It remains to install it on the window frame using z-shaped staples.

Tips from experienced installers

When choosing a profile, pay attention to its resistance to ultraviolet radiation. The higher it is, the longer the grid will last. A cheap box will begin to crack in 2-3 years, and buying too expensive is impractical.

Instead of Z-shaped brackets, corner stoppers can be used to secure the mosquito screen. They are cut out by a grinder from a stainless steel sheet with a thickness of 0.5-0.7 mm.

Following these recommendations, you can easily make mosquito nets for windows and balcony doors with your own hands. The main thing is to carry out all operations carefully, without unnecessary haste. And then the finished mesh will last more than one year, reliably protecting your home from insects. For the sake of such a result, it’s worth working hard, isn't it?

We buy in Leroy a set with metal. frame for 500 rubles. we collect it ourselves and as a result we have a grid as from the manufacturer.