Labeling features of linoleum depending on the properties of the coating

Content:

For many years, linoleum remains the most popular and sought-after type of flooring. This is due to the high wear resistance of the material, environmental safety, ease of installation and low maintenance, a variety of colors, budget cost. In order for the buyer to learn about the properties of the finishing material, there is a marking of linoleum. Of course, choosing the right cover in the store, any person will first pay attention to the color and texture. However, knowledge of special signs will help to more thoroughly understand the features of the coating and choose the most suitable for a particular room.

History of occurrence

It is believed that the impetus for the invention of linoleum was the usual oilcloth used in everyday life since 1627. At that time, this material was a fabric soaked in wax, resin, and linseed oil. This composition provided high strength and waterproof material.

The first linoleum samples appeared in 1863 thanks to the works of the English industrialist Frederick Walton. Translated into Russian, linoleum means "oiled canvas", from linum - linen, fabric, oleum - oil.

According to Walton’s technology for the manufacture of linoleum, burlap, jute fabric, on which oxidized linseed oil (linoxene) was applied, was used as a base. The result is a dense, abrasion resistant, but brittle fabric. In the course of research, it turned out that the new material is poorly flammable and so durable that it is impossible to push it with either a heel or a furniture leg.

Three years after Frederick patented his discovery, the mass production of new finishing material began. The fast pace of introduction of new technology in Europe was explained by the demand for flooring in construction and the simplicity of production organization.

Separation by composition

Today, the manufacturing process of linoleum fundamentally resembles the technology of past years. Natural coating is made from natural raw materials: linseed oil, gum, wood, cork and linoleum flour, limestone, colored and white pigments, jute fabric. The amount of binders in natural linoleum should not exceed 30%.

Linoleum from natural ingredients is used in children's institutions and hospitals. This type of coating is also suitable for residential premises, as it is completely safe for health, wear-resistant, and due to linseed oil, which is part of it, has a bactericidal effect.

Modern chemists have developed artificial materials that completely imitate natural ones and surpass them in many properties. One of them is linoleum, which was among the first to be improved. Despite the fact that the name “linoleum” has been preserved and forever fixed to this coating, it is correct to say “artificial linoleum”, since this is, in principle, a completely different material.

PVC linoleum has several advantages over its natural counterpart. It is inexpensive, and anyone can afford the finish of the floor in the apartment with this material. The ease of installation and a wide range of shades and patterns used in the production of artificial linoleum captivates. The coating retains heat well, does not electrify, does not fade in the sun.

Basis classification

There are many varieties of flooring. They can differ in the presence of a base, in wear resistance, the type of front surface and many other parameters. When marking each type of linoleum, specific designations are used.

By the presence of a base, all products are divided into two large classes: linoleum, which has a base, and without a base.

- Linoleum without a base

Typically, such linoleum has a thickness of about 3 mm, consists of more than two layers, is very durable, does not wear out for a long time and does not change color. Some types of coatings without a base have a protective layer of up to 0.55 mm. High fire resistance, electrical resistance, water resistance and the presence of a slight roughness on the surface of the finishing material allows it to be used in saunas, baths and pools, bathtubs and toilets.

In some products, the manufacturer specifically inserts carbon filaments to reduce static electricity. Linoleum with antistatic properties finish floors in office rooms with a large number of household appliances.

There are types of coatings with the effect of sound absorption. When walking on the floor trimmed with such material, no steps are heard, the load on the legs and back is reduced.

- Foam based

A foam-based PVC coating has a thickness of up to 3.5 mm. Durability, the possibility of use in a humid room, a wide palette of colors and patterns makes this type of material in demand for the decoration of living rooms.

- On tissue subbasese

Linoleum on a fabric base in thickness is on average up to 5 mm and consists of two layers. The bottom layer is made of natural or synthetic fabric (jute), the top is PVC.

It is used for decoration of premises with low traffic to improve thermal insulation.

Division of wear resistance

The wear resistance of linoleum depends on the thickness of the protective film applied over graphic printing. In order to reduce the cost of production and increase the resistance of the material to wear, a new technology for drawing patterns was developed. Now the paint is not just applied to the surface, but interspersed inside a layer of PVC. This coating was called commercial, and the classification for wear resistance is as follows:

- home - used in houses and apartments;

- semi-commercial - for offices and premises with medium traffic;

- commercial - used in office and industrial premises with high traffic.

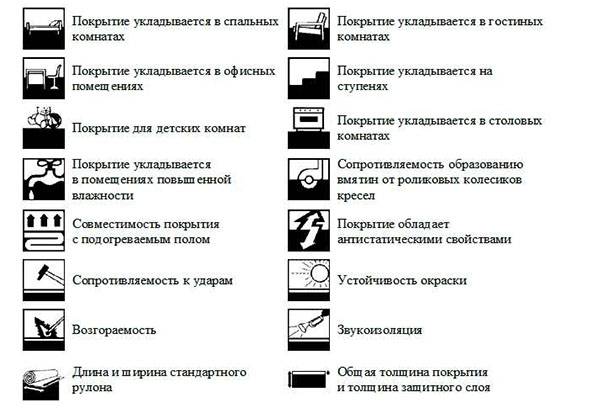

Designations of linoleum

To determine the quality of the coating, there are many different parameters. This is the thickness of the protective layer, mass, combustibility, water resistance, thermal conductivity, resistance to chemicals and ultraviolet rays, the ability to absorb noise and dampen static charge, bactericidal properties.

To indicate the characteristics of each type of material, manufacturers have developed special badges and symbols. What information can be gleaned from the labeling, the author of the site purityis.decorexpro.com/en/ found out.

If the buyer doubts whether the selected cover is suitable for his apartment, he should be guided by the first digit in the marking:

- 1 - minimum cross;

- 2 - a dwelling with an average cross;

- 3 - office and office space;

- 4 - production area.

By the second digit, you can find out what kind of load the selected type of flooring can withstand. The highest load is denoted by four, the lowest - by unit. For example, for a bedroom you can buy linoleum of rank 21, and for a dining room, 23 or 24 is better.

Different manufacturers of linoleum markings may be different, but mainly PVC linoleums made in our country have the following designations:

- LP - PVC linoleum;

- T - woven base;

- NT - non-woven backing;

- RK - the basis of the regenerate, a substitute for the skin;

- OP - monophonic printing;

- MP - multi-ton printing.

Important!

Before you buy your favorite flooring, you must carefully read the labeling or ask the seller about the properties of the goods.

Knowing how to decipher the designations on a roll of linoleum, it is much easier to choose the right material.

European marking

For linoleums manufactured abroad, the UREC marking is used:

- U - abrasion resistance (from UО to U4);

- R - residual deformation (from PO to P4);

- E - water resistance;

- FROM - resistance to chemicals.

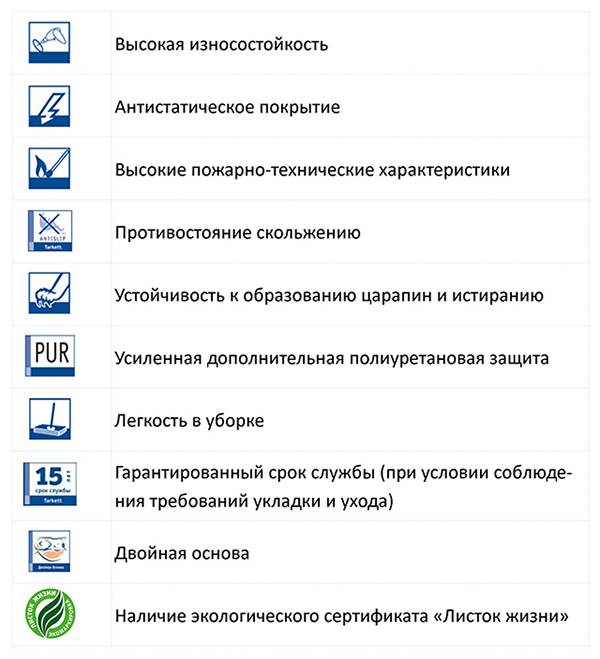

Many manufacturers give their products additional properties, which are indicated using special icon pictograms. This can be increased resistance to electric charge, ease of cleaning, high fire and technical characteristics, resistance to scratching, the presence of an environmental certificate “Leaflet of life”.