Choose a foam adhesive

Content:

Penoplex is a modern finishing material used for warming rooms. It was invented relatively recently, only in the middle of the last century. However, today this insulation is widely known and in demand all over the world, and simplicity of installation plays a significant role in gaining such popularity. To attach the panels and insulate the building, you must correctly select the adhesive for the foam and follow the instructions. The choice of adhesive composition depends on the place of work, the nature of the surface on which the boards are glued, humidity, air temperature and other factors.

Heater penopleks

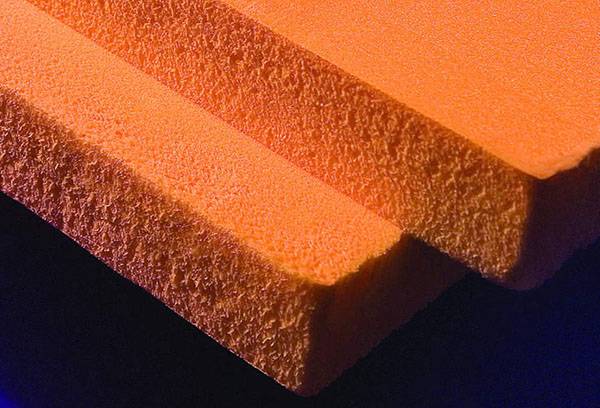

Penoplex in composition and structure resembles foam. For its manufacture, polystyrene particles are used, which foaming under the action of chemical reagents, forming a cellular mass. During processing, the free cavities are filled with freon, which subsequently evaporates and is replaced by air.

The result is a lightweight porous material with high thermal insulation performance. Penoplex is produced in the form of plates of different sizes, so when buying material, you need to consider whether the decoration will be carried out inside or outside the room and which part of the building needs to be insulated: facade, walls, roof or foundation.

To attach polystyrene panels to the treated surface, you will need a special adhesive for foam. Special attention must be paid to the choice of adhesive. The main thing is that the glue provides good adhesion and does not contain substances harmful to the health of people living in the room.

Technical characteristics of foam adhesive

All types of glue differ in adhesion strength and are used specifically for those surfaces and in such conditions as the manufacturer indicates on the packaging.

The detailed instructions for the preparation of glue and a description of the technical characteristics of the composition contain the following information:

- recommended temperature range when working with the adhesive composition and operation of the room;

- air humidity;

- type of the processed surface.

There are several types of adhesive for foam, varying in composition.

- Mineral In the composition of mineral (cement) adhesive mixtures, 95% of the total volume is occupied by cement and sand, and the remaining 5% is accounted for by various additives. It can be polymer modifiers, anti-frost additives, water-retaining inclusions. Mineral-cement adhesives are used mainly for outdoor work, in particular for bonding foam to concrete.

- Polyurethane One-component polyurethane adhesive for mounting plates made of extruded polystyrene foam contains isocyanate oligomers that displace propane and isobutane. The adhesive layer does not collapse under the influence of moisture and mold, is not amenable to aging and creates strong joints with concrete, brick, wooden substrates. It can be used for both indoor and outdoor use.

- Waterproofing. Most often, waterproofing adhesives have a bitumen base and are used in the exterior decoration of basement rooms. The composition of adhesives in this group contains substances hazardous to human health, therefore they are not recommended for use for wall insulation inside a residential building.

When deciding how to glue foam, do not forget about the structure of the insulation itself. Foamed polystyrene is rather capricious, and the surface of the plate can be destroyed by contact with aggressive adhesive.

Important!

The interior decoration of residential apartments should not be planned for the winter, when it is especially difficult to ventilate the room. After all, any glue, when dried, exudes an unpleasant odor.

Adhesive for foam should not contain the following substances:

- combustible materials - kerosene, diesel fuel, gasoline;

- aromatic compounds - toluene and benzene;

- coal and polyester resins;

- solvents;

- formaldehydes.

Before you make a purchase, you need to carefully study the composition of the adhesive and the manufacturer's recommendations posted on the packaging of the goods.

Which glue is better - an overview of products from well-known manufacturers

Adhesive for mounting polystyrene panels is available in various forms. These can be ready-to-use formulations or dry mixes that must be properly diluted before use. Foam in cylinders is very convenient. Pressurized adhesive is removed by pressing a special lever.

Russian and foreign manufacturers are constantly improving old ones and are developing new technologies for producing durable and harmless adhesive compositions. The Polish Atlas concern and the German company Henkel occupy a leading position in this trading segment. Here are a few products that have become a brand among adhesive products for the installation of polystyrene boards.

- Atlas Stopter K-20

A high-quality mixture used to adhere polystyrene panels to any surface with a mineral base. The adhesive layer created using this product is resistant to frost and does not collapse under the influence of water. Used in the facade insulation device, the adhesive is able to create a high-quality reinforcing layer. Increased elasticity and adhesion, as well as additives that minimize shrinkage, determine the special use of this glue in building insulation systems. A bag weighing 25 kg costs 320 rubles.

- Atlas Plus

Universal adhesive that can be used not only for foam, but also for ceramic tiles. It creates a very elastic and strong bond, therefore it is recommended for gluing surfaces subject to deformation. The adhesive composition is used in the decoration of underfloor heating and open balconies, wooden floors, particleboard, to connect the foam panels together. A bag weighing 25 kg has a cost of 600 rubles.

- Ceresit CT 84

Ceresit is one of the world famous brands owned by the German company Henkel. Ceresit polyurethane foam is used to insulate buildings with expanded polystyrene panels. The adhesive is applied to the surface with a mounting gun and sets in 10 minutes even at high humidity and sub-zero temperatures. The components of the adhesive do not have secondary expansion, so the seams between the sheets do not diverge. One of the advantages of Ceresit glue is its very low consumption. One 250 ml bottle is enough for 5 square meters. m

- Tytan Professional

Polyurethane foam goes on sale in the form of an aerosol and is used for exterior and interior insulation of buildings with foam. Glue for foam does not have an unpleasant odor, is safe to use, contains elements that prevent the spread of fungus and mold. The cost of a 750 ml cylinder is 270 rubles. One spray is enough for 10 square meters. m. surface.

Instructions for the use of adhesive for foam

Getting started with penoplex, it is necessary to prepare the following tools and materials:

- foam panels;

- primer;

- roller or brush;

- degreaser;

- spray gun.

It is better to stick insulation with an assistant, but you can cope alone. The main thing is to follow the instructions and do the work carefully.

The surface to be insulated is cleaned of dirt, old paint, primer and degreased by spraying the mixture with a spray gun. If necessary, prepare the glue according to the instructions supplied by the manufacturer.

Apply adhesive to the wall surface and insulation.There are several ways to do this:

- points - large drops of glue are applied at a distance of 25 cm from each other;

- stripes - smear the edges with glue and draw two stripes in the middle of the canvas;

- continuous layer - apply the composition to the insulation plate, leaving no gaps.

After the adhesive composition is distributed, the insulation is applied to the wall or ceiling and held until it sticks to the surface to be treated. Then proceed with the installation of the next panel.

Tip

If a person for the first time independently performs thermal insulation with foam plastic plates, it is better to use glue in the form of an aerosol. It is much easier to work with it than with other adhesives. In addition, when using polyurethane foam less dust and dirt, so it is great for indoor use.

With the help of foam plastic plates, it is possible to insulate the walls and ceiling of the room, the roof and the facade of the building. The main thing is to choose a suitable adhesive that can provide a solid connection of the treated surface with heat-insulating material and does not contain harmful chemical elements.