How to properly and safely work with epoxy resin?

Content:

When epoxy was invented in the 1950s, problems with bonding various materials were resolved. The new compound has found application both in industrial production and in domestic conditions. Gradually, various compositions appeared, the possibilities of their use expanded. Now this substance is used not only for bonding. Epoxy is used in the manufacture of insulating materials, fiberglass, compositions are used in waterproofing, the device coatings exposed to moisture and aggressive substances. The solution is poured into molds and various products for industrial use and design work are obtained.

The composition and properties of the adhesive

Depending on the components, the connection of the parts can be strong and tough or soft and elastic like rubber. After polymerization, a reliable seam is obtained. The dried polymer cannot be dissolved or melted; the compound can be called eternal. The resulting products are allowed to be used both in bedrooms and in children's rooms: a cured epoxy resin does not emit harmful substances. If you need to glue materials with a smooth, pore-free surface, the best tool is hard to come up with.

As a hardener, various substances are used. Their selection depends on the connection requirements, product operating conditions, and many other factors. As a polymerizing agent, on which the characteristics of the adhesive largely depend, you can use:

- phenols;

- tertiary amines;

- polycarboxylic acids.

Epoxy resin is a generic name for an adhesive of 2 components, and the brands and compositions of the product exist different. For domestic use, grades capable of drying at room temperature are usually used. In industries, sometimes you need to work on a hot surface, in conditions of high humidity or exposure to an aggressive environment. Depending on the composition of the components, a solution can be prepared that can create a strong connection both at a temperature of + 200 +C and in sea water.

How to dilute epoxy?

If you do not like to prepare a working solution, you want to open the tube and immediately smear the surfaces to be glued, epoxy is not for you. She does not glue anything herself - to get a reliable connection, you need to add a hardener and mix the composition well. The ratio of components depends on the type of resin, and on the composition of the hardener. If you make a mistake in the ratios, the product will not be strong enough, it will become less resistant to temperature extremes, moisture and other conditions. The correct composition should be prepared according to the instructions, which describe in detail how to dilute the epoxy resin.

One of the types of epoxy - EDF glue - manufacturers recommend diluting in proportion: 6 parts of resin and 4 parts of hardener. Other brands have a ratio of 10: 4 or 10: 6. Pour the components into a special container and mix thoroughly. If the density of the resin is too high and there are difficulties with mixing, slightly warm it in a water bath. If you want to add dyes, use only dry powder pigments. Any drop of moisture can adversely affect the quality of the adhesive.

Tip

To prepare, mix and apply epoxy, use utensils and tools that are not a pity to throw out.To clean them from the glue is very difficult, and there is no guarantee that you will wash off the entire composition without residue.

Sometimes it is necessary that the polymerization is quick and the product can be used in a few hours. It is useless to experiment with the proportions of the composition; this does not affect the reaction rate. Better heat the bonded joint, every 10⁰C will speed up the hardening process by 2-3 times. There is a two-component epoxy resin with a special composition that can create a strong bond quickly and at low temperatures.

How to work with epoxy resin, material consumption per 1 m2

For the work to be done efficiently, surfaces should be well prepared. Epoxy must adhere firmly to both surfaces, otherwise your product will quickly fall apart.

Before applying the resin, perform the following steps:

- clean the surface from dust and dirt;

- degrease parts with solvent or detergents so that they do not leave traces of oil and oil products;

- process glossy surfaces with sandpaper or a grinding wheel.

Tip

If you need to make bulk floors or other structures of large thickness, apply epoxy resin in a thin layer. When the first coating is hard, but still not sticky, apply the next layer and repeat until you reach the desired thickness.

Connect the surfaces smeared with glue, firmly press them to each other and fix. As a holder, you can use a strong rope, vise, clamps, cargo. In this position, the product should remain for about a day until the primary polymerization takes place. Then you can remove the mount, but you should not expose the connection to stresses, the epoxy has not yet gained strength. Complete drying usually occurs after 7 days at room temperature.

Often when working, the question arises of how much resin needs to be diluted so that the composition is enough for the entire volume and there is no large excess. Approximate consumption is 300 g per m2, but much depends on the thickness of the layer, surface texture and other factors. Do not breed more than 0.5 kg, because the composition dries quickly and you may not have time to spread and join all the surfaces.

How long does the epoxy dry?

The prepared solution can be used from 30 minutes to an hour, the time depends on the brand of resin and temperature. If the polymerization process has begun, it is futile to try to stop it with solvents or other means. It remains only to throw out a can of epoxy resin and prepare a new serving.

You can use the product when the polymerization process is complete. The duration of the process depends on the temperature at which the product dries. At + 20⁰C, the glue dries in a day, and the connection reaches its maximum strength in about 7 days. At + 100⁰C, the polymer forms in half an hour and will fully get stronger in 2 hours.

Sometimes you need to change the color of epoxy glue. You can add pigment to the composition. If you need to epoxy the surface onto which the polyester resin has been applied, wait until it is completely dry. Try not to apply the compounds in the reverse order, but if you need to apply the polyester resin to the epoxy resin, wait for the complete polymerization (at room temperature it lasts 7 days), and then clean the surface with sandpaper.

What temperature does the glue withstand?

Different types of epoxy are produced; its quality depends on the composition of the components. For domestic use, glue with a hardener of a cold type is most often produced. It can be used for gluing products that are not exposed to high temperatures: shoes, furniture, decorative finishes. What temperature the seam can withstand, manufacturers write in the instructions and technical specifications.

If you need to stick something on the fireplace, or repair a thing that is exposed to extreme heat, take a composition with a hot type hardener. Be sure to see what maximum heat the seam can withstand. Epoxy is a universal glue, but even a steelmaking furnace can’t stand the fire, do not expose the joint to too high a temperature.

The same applies to the temperature of glued surfaces. To work with epoxy on the street, glue is produced that hardens at subzero temperatures, there are compounds that will only harden when heated. Before going to the store, consider the conditions under which the product will dry and operate. The instructions will indicate whether this brand of glue is suitable for your work.

Epoxy Mistakes

For domestic use, grades are produced that do not require an exact ratio of resin and hardener. Such compositions are designed to prepare a small amount of solution, a few grams will be enough for you to repair shoes, furniture, install a mirror in the frame. The proportion is usually recommended: for 1 part resin, 1-2 parts of hardener, but the products are different, do not forget to read the instructions. Small doses are easy to mix manually in a jar or an old bowl, and for preparing large volumes it is better to use a special mixer.

After solidification, the materials remain glued forever. It is useless to look for information in directories, what is the melting point of the polymerized composition and how to dissolve it. Until the glue has set, consider whether you have connected the parts correctly or if you need to change their position. Then it will be impossible to fix the error.

If a lot of material is required, difficulties can arise. When mixing large volumes, there is a strong heat release, the composition quickly hardens. If the temperature rises too violently, smoke begins to emit, a spontaneous combustion of the mixture may occur. When buying, ask the seller or read in the instructions for how much mix this brand is designed for. For the manufacture of castings, self-leveling floors and other structures requiring a large amount of mortar, special formulations are produced. They do not overheat, solidify evenly, without bubbles. When preparing a large volume, you can’t just add the hardener and stir, the resin must first be heated to make it less viscous.

If the epoxy has been stored for a long time, it has become too thick and cloudy, put the can in a water bath and heat to a temperature of about + 60⁰C. Do not use thinners or solvents for this purpose, they are incompatible with epoxy resin - the composition will lose its quality, the connection will initially be fragile. Subsequently, the solvent will evaporate, the polymer will keep the bonded parts even worse. If, during the preparation of the composition, the mixture boiled, foam appeared, glue should not be used. Prepare a new solution, as recommended by the instructions for use.

Tip

Be careful when heating the composition in a water bath. If drops of water get into the glue, the solution becomes cloudy and loses its quality.

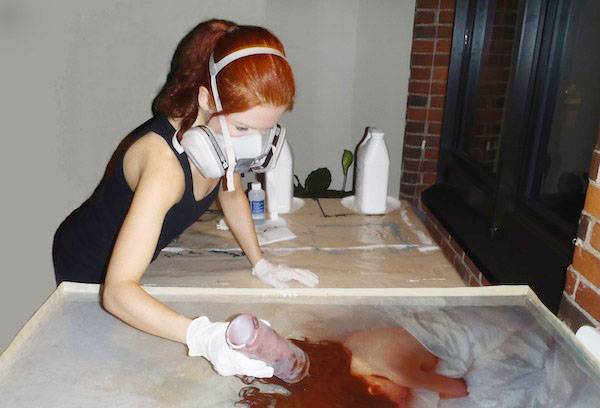

Is epoxy harmful to health?

When frozen, the epoxy adhesive is safe for health, does not emit harmful substances into the air, but when preparing the solution and working with it at home, safety precautions must be observed. To prevent fumes from irritating the respiratory system, use a respirator. Work with harmful compounds preferably in the open air or in non-residential premises. If you use glue in the apartment, open the window.

The components of epoxy glue have a harmful effect on the skin: they cause burns, irritations, and dermatitis. To protect your hands, wear gloves with a protective cream. If the composition gets on the body, wipe the affected area with denatured alcohol and wash with soap and water.Do not use food utensils for work; epoxy must not come into contact with edible products.

Keep components out of the reach of children and animals. When working, make sure that the kids do not go into the room and are not interested in the contents of the can. If someone accidentally swallows epoxy glue or the composition gets into his eyes, immediately seek medical help.

You can glue any products with epoxy, you just need to choose the right brand of glue for specific jobs. Gain experience on small surfaces where the composition should be applied in a thin layer. When you learn how to mix components correctly, you will understand how to dilute epoxy without boiling and bubbles, you can proceed to more complex processes: do bulk floors, cast decorative elements in molds. Learn the different techniques for using epoxy, and then you will not need many other types of glue.